Management Guideline

Signification:

AMAZING is a company specializing in chip design and R&D without operating manufacturing facilities. It focuses on the integrated circuit and outsources the wafer manufacturing to midstream and downstream wafer foundries, as well as the back-end packaging and testing to packaging plants. The upstream, midstream, and downstream operations form a seamless strategic partnership by closely working with professional and qualified foundries for years. In addition to improving quality, cost, and delivery, cooperating with suppliers to mitigate the environmental and social risks arising from production is one of the goals that AMAZING strives for.

Policies and Commitments:

AMAZING executes supplier management based on the three pillars of ESG in accordance with the principles of Supply Chain Sustainability Management. From new supplier selection to regular key supplier audits and evaluation, ESG issues are always included in the assessment. If suppliers are unable to meet the requirements, we will provide timely advice and assistance. We look forward to working with suppliers to contribute to the planet and society.

Goals:

Short-term:

- Ensure that 100% of our suppliers have signed the Supplier Code of Conduct.

- Ensure that 100% of our suppliers have completed assessments and audits with all the ESG-related items.

Medium and long-term:

- Encourage suppliers to be actively concerned about global ESG issues and respond to them.

- Implement the conflict-free mineral sourcing policy.

- Conduct periodic supplier assessments and hold regular meetings.

- Remain a local sourcing rate above 25%.

Actions:

- Both new and qualified suppliers are required to sign the “Code of Conduct for Outsourcing Partners.”

- Add ESG assessment items to the annual audit and incorporate sustainability performance into the evaluation of long-term cooperation.

- Regularly update regulations and request suppliers to provide hazardous substance testing reports at regular intervals.

- Conduct conflict-free surveys periodically and ask suppliers to provide evidence that the raw materials used do not come from conflict regions.

Achievements over the years:

Please select the year from the list:

- 100% execution of conflict-free minerals policy

- Implementation of hazardous materials management plan

- Remaining a local sourcing rate above 25%

Process to Sustainable Supply Chain Management

As a design company at the forefront of the semiconductor supply chain, AMAZING relies on suppliers to complete its middle and back-end manufacturing process, forming a specialization system. Therefore, collaboration with suppliers will be an essential element to build a sustainable supply chain. Based on the Sustainable Supply Chain Management Guideline, we have developed supplier management procedures, from introducing new suppliers at the very beginning to supplier evaluation and audit. In addition to business considerations such as quality, cost, and delivery, we have recently included ESG-related items, required all existing suppliers to sign a Supplier Code of Conduct, and conducted ESG Risk Assessments and ESG ratings at regular intervals for suppliers. We also adhere to a 100% Conflict-free Mineral Sourcing Policy, adopt green product standards recognized globally and by all customers, and ask suppliers to manage hazardous substances. By maintaining a certain proportion of local sourcing, we try to reduce the impact of good transportation on the environment and increase job opportunities for local workers. We aim to create a sustainable supply chain with suppliers through these measures.

-

Targets

New supplier review

DescriptionConduct a comprehensive inspection of various quality management systems for new suppliers. A small batch project is used to verify their manufacturing capabilities. The Supplier Code of Conduct must be signed, and an ESG Risk Assessment shall be performed. Then, an on-site audit will be conducted as the final step before approval to ensure that new suppliers can continue contributing to the sustainable supply chain after becoming AMAZING's qualified suppliers.

Frequency and Procedure -

Targets

Regular supplier meeting

DescriptionA regular monthly meeting shall be hold with suppliers to discuss the quality and production issues of the previous month in order to provide them with suggestions and assistance in a timely manner and maintain long-term partnerships.

Frequency and ProcedureMeetings with major suppliers shall be held every month.

-

Targets

Periodic supplier assessment

DescriptionSuppliers shall be collectively assessed quarterly according to the four quadrants: quality, cost, delivery, and technical services. To recognize outstanding performance, trophies will be awarded every year to suppliers with excellent scores. For supplier with scores lower than the standard, we will provide with guidance and assistance to deliver a positive impact within the sustainable supply chain.

Frequency and ProcedureMajor suppliers shall be assessed quarterly. The fourth-quarter evaluation is calculated based on the year's total average.

-

Targets

Supplier audit

DescriptionMajor supplier audits shall be conducted every year to verify the implementation of their quality and management systems. Once a deficiency is identified, suppliers will be required immediately to propose an improvement plan to address the problem. The supplier audit shall include ESG items to ensure suppliers conform to the sustainable development goals.

Frequency and ProcedureMajor supplier audits shall be conducted every year.

Supplier Code of Conduct

To secure the workplace safety of our supply chain partners, ensure that employees deserve to be treated with respect and dignity, be concerned about environmental protection during the manufacturing process and material selection, comply with local regulations and personal ethics in business operations, AMAZING established the “AMAZING Supplier Code of Conduct” based on the “RBA Code of Conduct” referring to the Human Rights Norms recognized internationally. Key suppliers are required to sign the “AMAZING Supplier Code of Conduct” and adhere to the requirements. New suppliers must also sign it before being one of our qualified suppliers. We expect that the whole supply chain may understand the importance of being part of a sustainable enterprise and contribute together to the promotion of social responsibility that is valued globally.

Risk Assessment for Supplier ESG Management

Today, our customers and the general public are much more concerned about ESG-related issues. In addition to the requirements for quality, price, and product performance, people have started caring about the enterprise's actions toward employee rights, compliance with local regulations, pollution mitigation, and their impacts. AMAZING assesses the sustainable management capabilities of suppliers on three aspects – economy, environment, and society to avoid the risks of improper ESG management by suppliers, resulting in environmental pollution, workforce shortage, quality deviation, and other situations that may affect company image and competitiveness. For suppliers with inefficient ESG management, AMAZING will also provide assistance to help them not only aim to make profits but also have responsibilities to contribute to the society.

-

Item

Economic aspect

Management policyMeasures for quality system management and continuous improvement to achieve the quality standard and maintain economic stability.

Management standards- ISO 9001 Quality Management Systems

- IATF 16949 Automotive Quality Management System

Assessment weight34%

-

Item

Environmental aspect

Management policyEnsure that suppliers do not use hazardous substances and have tried their best to minimize impacts on the environment during production.

Management standards- ISO 14001 Environmental Management Systems

- QC0800000 Hazardous Substance Process Management

- Sony GP

Assessment weight33%

-

Item

Social aspect

Management policyEnsure that suppliers fulfill their social responsibilities, comply with labor rights, and provide a safe and health work environment.

Management standards- ISO 45001 Occupational Health and Safety Management

- RBA/SA 8000 Social Accountability Standard

- Corporate Social Responsibility (CSR) Report

Assessment weight33%

Results of Certification Acquisition among Suppliers

| Aspects | Management Standards | Evaluation complete rate (100%) | Supplier Acquisition Rate (%) | Overall Achievement Rate (%) |

|---|---|---|---|---|

| Economic | ISO 9001 Quality Management Systems | 100 | 100 | 97 |

| IATF 16949 Automotive Quality Management System | 100 | 94 | ||

| Environmental | ISO 14001 Environmental Management Systems | 100 | 100 | 94 |

| QC 080000 Hazardous Substance Process Management /SONY GP | 100 | 88 | ||

| Social | ISO 45001 Occupational Health and Safety Management | 100 | 88 | 59 |

| RBA/SA 8000 Social Accountability Standard | 100 | 24 | ||

| Corporate Social Responsibility (CSR) Report | 100 | 65 |

Results of Supplier ESG Assessment:

-

ESG Assessment Results (points)

Number of Suppliers

80 ~100 分11

60 ~ 79 分5

< 59 分1

Based on suppliers' certification acquisition and calculation by the assessment weight, up to 94% of suppliers are classified as medium to low risk, and only one is high risk. AMAZING will help the high-risk supplier improve risk scores.

Green Product Management

To fulfill its responsibility for environmental sustainability, AMAZING established the “Green Product Management Procedure” per international regulations and customer requests. By keeping abreast of global regulatory shifts and considering additional customer requirements, we regularly update the hazardous substance management list and periodically inspect the composition of each material for compliance with standards and requirements to achieve the goals of green production.

Directives / Regulations / Acts

-

EU

- RoHS

- PFOS/PFOA

- REACH SVHC/REACH Annex XVII

- Halogen Spec

- Packaging and Packing Waste Directive (PPWD)

U.S.A.- U.S. Conflict Minerals Law

- TSCA

- TPCH

- CP65

China- China RoHS2

Customers- SONY GP(SS-00259)

- Samsung Product Environment Management System – Business Operations

- AUO Regulations of Hazardous Substance for Green Product

- INNOLUX Restricted Substances Management Standard

- Quanta General Specification

Conflict-Free Minerals Policy

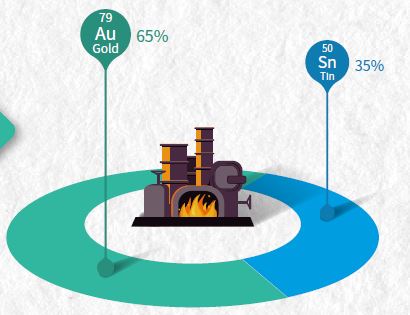

In recent years, the social and environmental issues arising from raw materials for electronic products and their manufacturing processes have gradually attracted worldwide attention. For instance, there are many social and ecological problems, including human rights violations and severe armed conflicts caused by armies and rebel groups in the Democratic Republic of the Congo (DRC) and neighboring countries through mining and mineral trade, thus triggering international controversy. The conflict minerals currently include the metals tantalum (Ta), tin (Sn), tungsten (W), gold (Au), cobalt (Co), and mica. The minerals mined in the DRC and from mines controlled by armed groups are called “conflict minerals.”

As an eco-friendly global corporate citizen, AMAZING supports the Responsible Business Alliance Code of Conduct (RBA Code of Conduct) and the Conflict-Free Sourcing Initiative (CFSI) founded by the Global e-Sustainability Initiative (GeSI) to defend people's rights and mitigate armed conflicts in the DRC and its neighboring countries. Hence, we declare and promise not to use conflict minerals from uncertified smelters in conflict-affected areas and require our suppliers to adhere to AMAZING's metal sourcing policy.

AMAZING hereby makes the following commitments:

- Our suppliers do not purchase conflict minerals from the DRC and neighboring countries.

- AMAZING conducts due diligence on supplier metal sources and adopts the Conflict Minerals Reporting Template (CMRT) released by CFSI and the Extended Minerals Reporting Template (EMRT) as questionnaires. The data filled by suppliers will be verified with the conformant smelter list on CMRT's website.

- We require suppliers to disclose their mineral source and expect all suppliers to adhere to our conflict-free minerals policy. Through responsible sourcing management, we ensure that supplier soucing does not come from conflict regions and meet customer and legal requirements.

RMI conformant smelters Total: 17 (100%)

Local Sourcing

Due to sourcing limitations and product attributes, the wafers used in AMAZING's products fabricated in the front-end process are suitable for local production, while there is a tight capacity available for back-end packaging to support the demand. So, our local sourcing focus is mainly on wafers, and the back-end packaging process is done outside of Taiwan. Currently, the proportion of local sourcing remains at over 25%. We will gradually increase the local packaging quota to diversify production risks in a single region in addition to lowering carbon emissions generated during product transportation. It may also help us to build closer partnerships with Taiwanese suppliers to create value in the local supply chain.